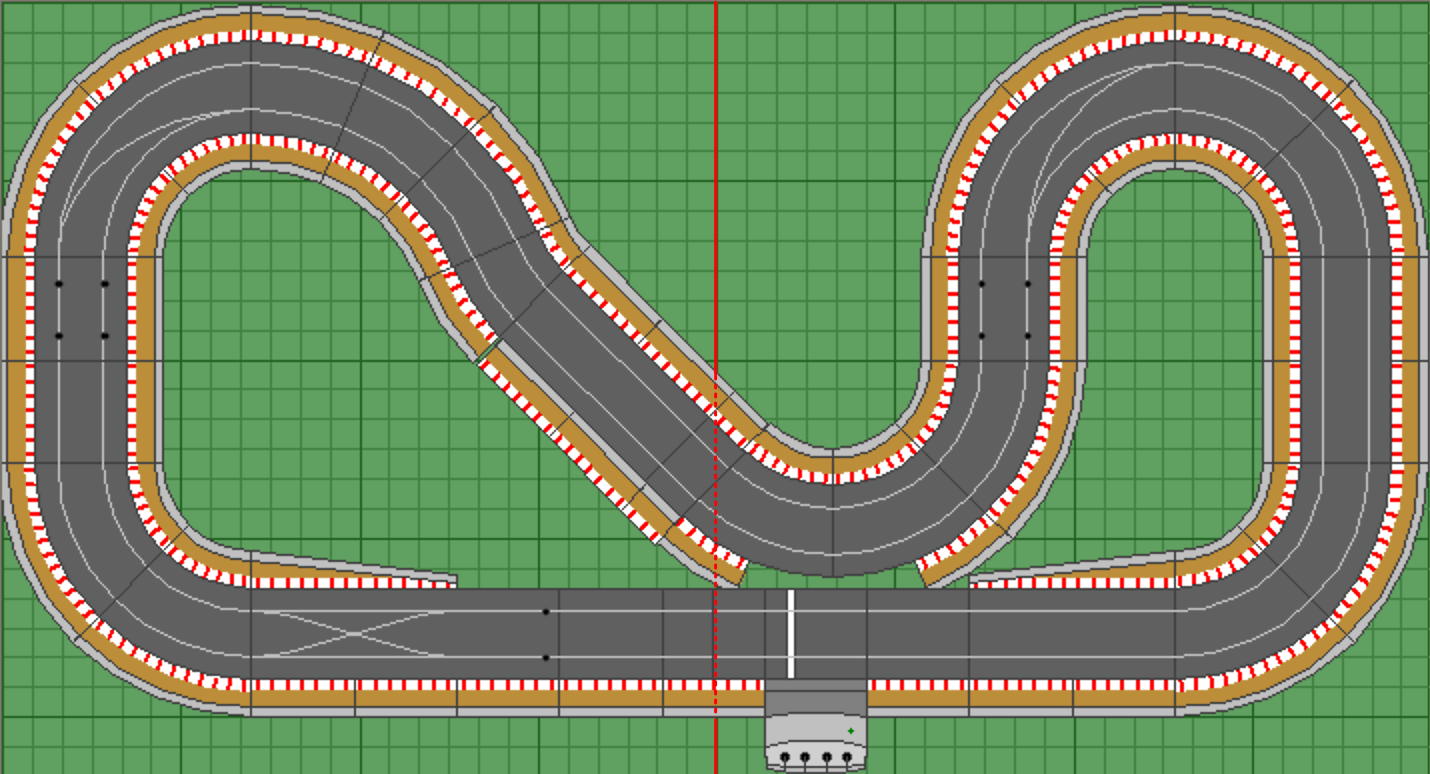

The corner lane changers were only included to replace an inadequate amount of available standard curves. The red line indicates where the track surface will be split for storage.

Having agreed on the layout, O'Brie organised and cut the 1/2" plywood sheets into two pieces for me and four for him and we each went about preparing them for use. O'Brie will certainly post some pics of his, but here are some pics of what I've spent Thursday and Friday afternoon and the whole of yesterday doing.

Because my track would be placed on the 71" x 30" folding table that's usually behind the driver station at FRC, I had to attach some braces to hold the two pieces in place squarely on the table without sliding around:

Here's how the table sits:

Its a perfect fit when upright:

Of course I had to paint the wood so that it looks properly finished and to help preserve it. As with the FRC track, the underside and edges were done in white (this was the last thing I did on Thursday afternoon):

On Friday afternoon, I painted the top grass-green before jumping on my bike for my 35 minute workout:

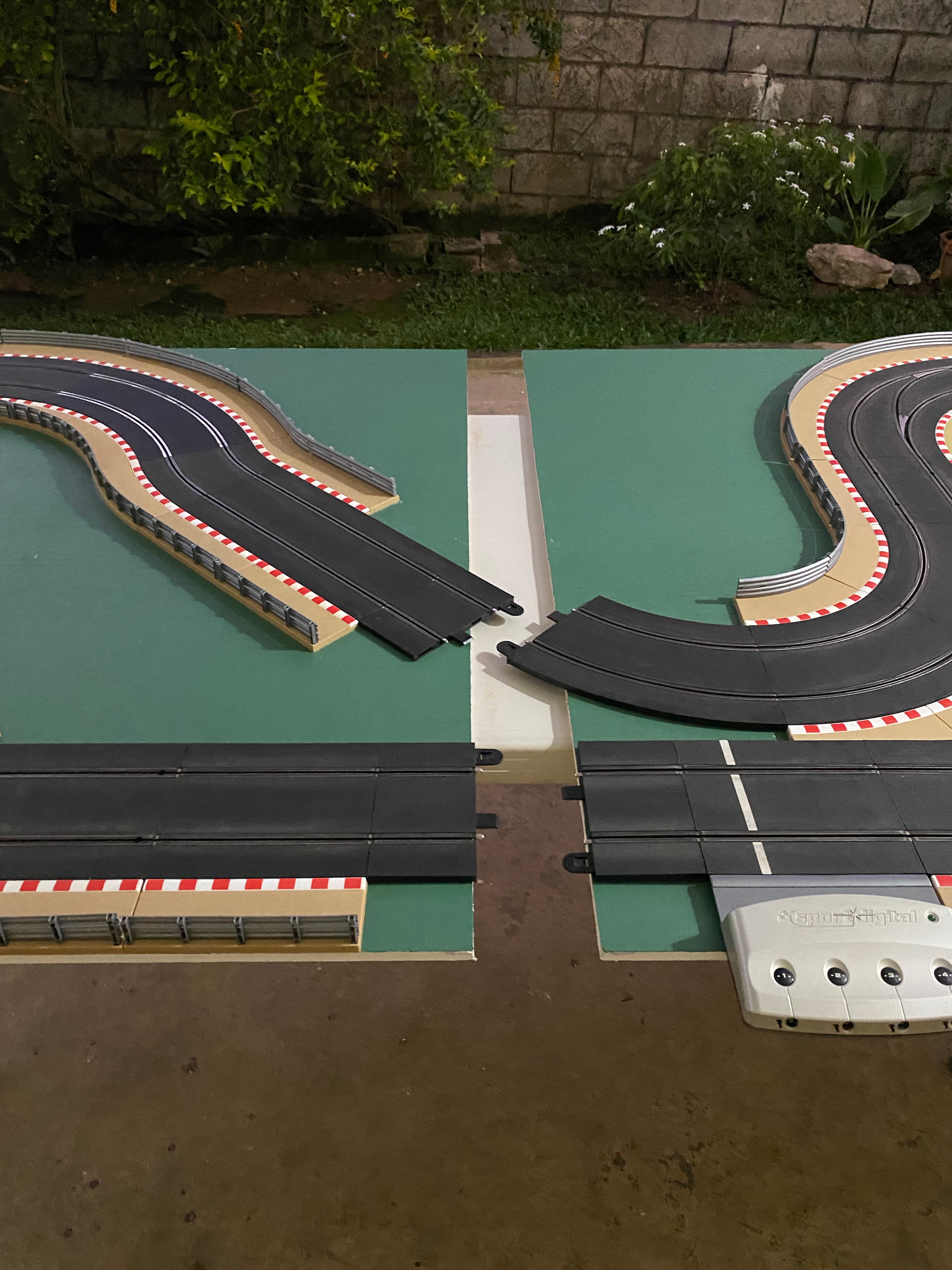

Yesterday was a long day. I spent the whole time up to around 7:30 PM with track-related tasks. One of the longest was going through plastic storage bins in our overpacked backyard storage shed, moving around some pretty heavy stuff, searching for the track pieces required. Each time I thought I had everything and repacked all the heavy stuff, I'd find that there were missing or wrong pieces, particularly in the case of the borders. I eventually even had to modify an R4 outer border to fit an R3 curve and cut some other borders to fit where necessary (pics lower down). Anyway, I finally got the track completed around 2:00 PM:

This shows the track split for packing up last night. Instead of gluing the track to the table, just the borders were glued down with silicone. This allows raising of the track pieces to disconnect them when packing away the track and even removal of track pieces for maintenance. The missing pieces in the pic are not glued down but are quickly and easily attached when re-assembling:

Here's the track stored (temporarily) in our front door passage:

This is the modified R4 border on the R3 curve. A piece on the left end of the red and white curbing got damaged and broke off while cutting it, and I had to super-glue on a bit of plastic to the underside. Its not perfect but does the job:

I cut the outer corner borders where the infield left-hander got close to the main straight and eliminated barriers in that section. This allows room for cars to slide without hitting the barrier:

To allow border and railing continuity on the short infield 1/4 straight, I carefully cur a border and its railing in half. The cut railings fit nicely in the cut borders where you'll notice a half-vertical on each one:

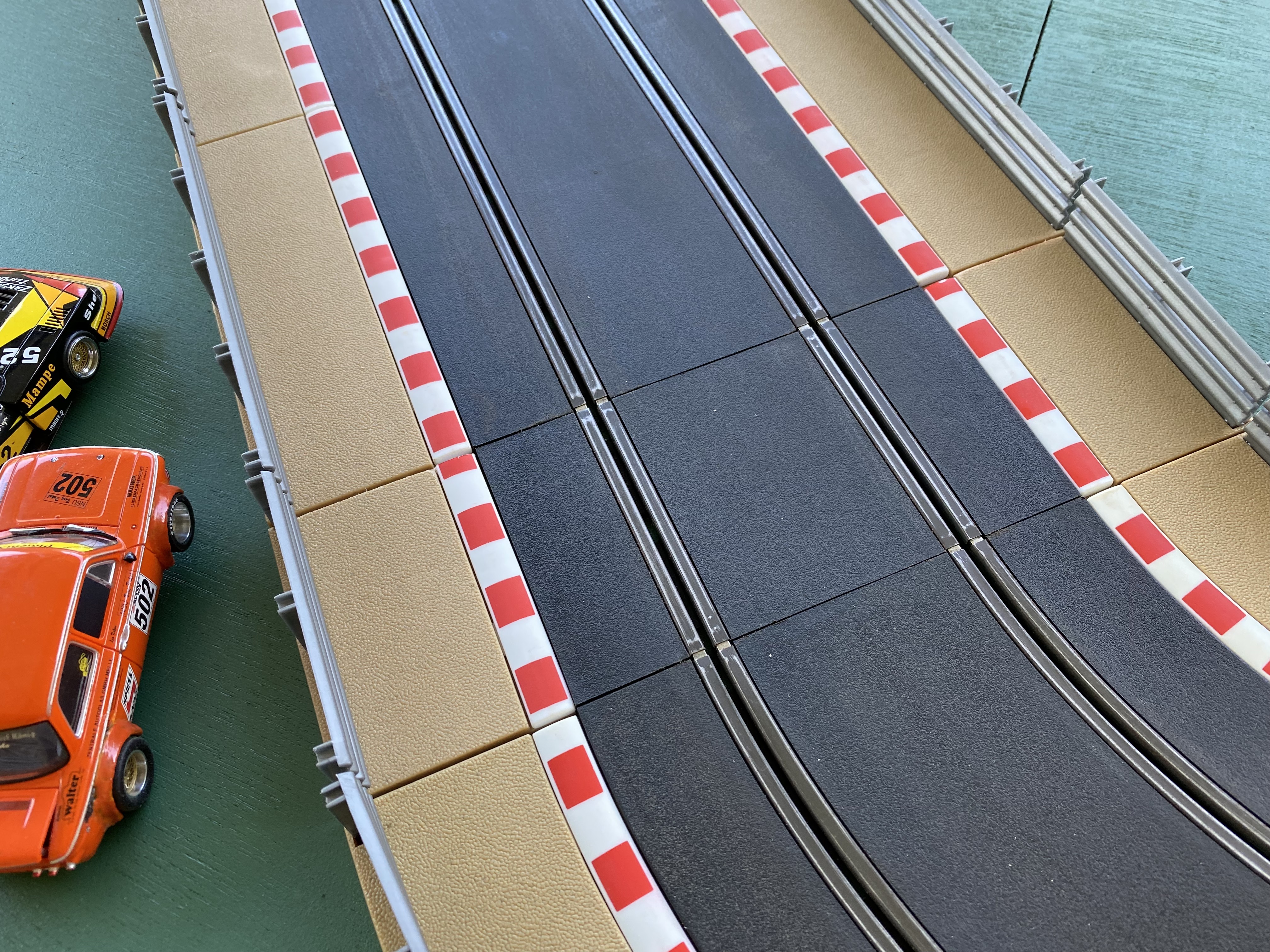

Here's a shot of some of my no-magnet cars on the infield. I got a chance to try each one and immediately was able to identify those that run well and some recently-converted to no-magnet (and previously-untested) which have definite issues. I even had my Cobra roadster suddenly take off flat out down the main straight and be the first (and only, thank goodness) to fly off the table and hit the concrete garage floor. Ouch! I've had some similar issues with it for a while and suspected that the chip is malfunctioning. This proved it. I've since spent some time thinking of how to build an easily-removable border fence for at least the side after the main straight to prevent future similar mishaps. I have some ideas, but of course, suggestions are welcome.

So, O'Brie and I now have identical test tracks from which to compare notes. More importantly, we can now test out cars before competition events at FRC and at least have them starting off reasonably prepared. Its also nice just to have a little fun on our own driving slot cars while we endure this awful lockdown situation.